Ariens ST11528DLE User Manual Page 27

- Page / 36

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

GB - 27

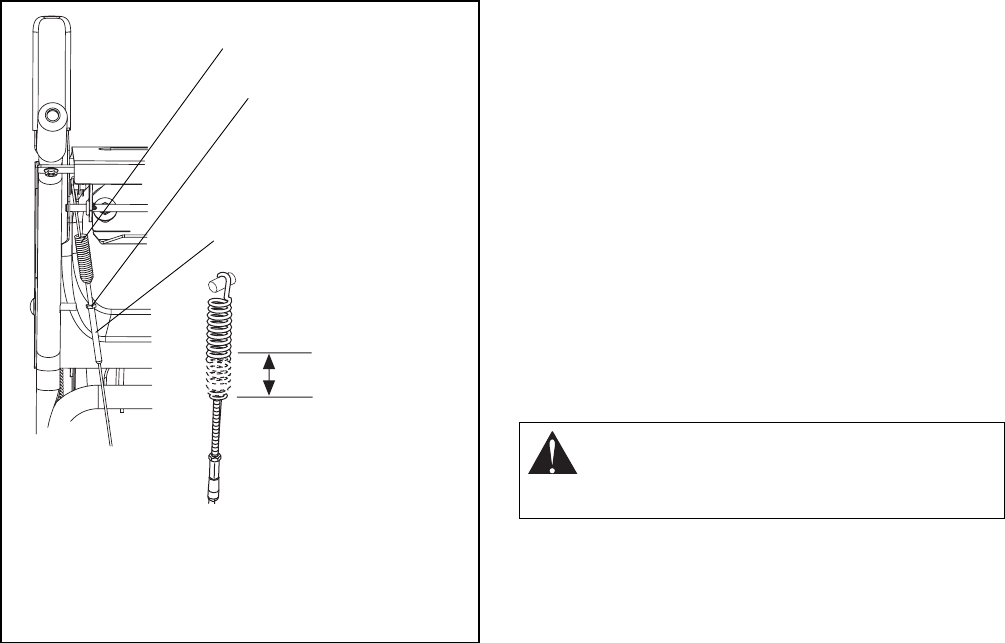

TRACTION DRIVE CLUTCH ADJUSTMENT

If drive slips, adjust traction clutch to compensate for

friction disc wear.

To adjust traction clutch:

1. Place speed selector in fastest forward speed.

2. Place unit in service position.

3. Measure the length of the traction drive clutch

spring at the top of the traction cable. See Figure

34.

4. Engage and hold the traction drive clutch lever

and measure the spring again. The spring should

be 1/2 -11/16 in. (12.7-17.5 mm) longer when the

lever is engaged.

5. Adjust spring extension.

a.With the traction drive clutch lever disengaged,

loosen the jam nut on the cable adjuster.

b.Turn the adjuster body up the cable for more

spring extension.

c.Turn the adjuster body down the cable for less

spring extension.

d.Finger tighten the jam nut, and then hold the

adjuster body with pliers and tighten the jam nut

with wrench.

6. Measure the extension of the traction drive clutch

spring.

7. Repeat step 5 until traction drive clutch spring

lengthens 1/2 -11/16 in. (12.7-17.5 mm) when the

traction drive clutch lever is engaged.

8. With the clutch disengaged, check that there is

more than 1/32 in. (0.8 mm) clearance between

friction disc and drive plate assembly.

IMPORTANT: If spring length cannot be adjusted

within specified range, see your Dealer for repairs.

ATTACHMENT DRIVE BELT

REPLACEMENT

Remove old attachment drive belt:

1. Shut off engine, remove key, disconnect spark

plug wire and allow unit to cool completely.

2. Remove belt cover (Figure 35).

3. Remove hair pin under the control panel

connecting the discharge chute rod from the

chute rotation lever and slide the discharge chute

rod forward.

IMPORTANT: Disconnect chute lock cable and

deflector cable, if equipped.

4. Remove belt finger (Figure 36).

IMPORTANT: Use care when rotating the belt fingers.

DO NOT bend belt fingers out of shape.

5. Remove attachment drive belt from engine

sheave (it may be necessary to turn engine

sheave using recoil starter handle).

IMPORTANT: To avoid bending bottom cover when

tipping unit apart, support handlebars firmly or tip unit

up on housing and remove bottom cover by removing

six cap screws before separating unit.

6. Support Sno-Thro frame and housing.

7. Remove hex bolts securing housing to frame

(three on each side). Tip housing and frame apart

on pivot pins (Figure 35).

8. Remove attachment drive belt from attachment

pulley (hold brake away from belt).

Figure 34

1/2 -11/16 in.

(12.7-17.5 mm)

1.Traction Drive Clutch Spring

2.Jam Nut

3.Adjuster Body

1

2

3

OS7205

OS7210

CAUTION: Always support Sno-Thro frame

and blower housing when loosening the cap

screws holding them together. Never loosen

cap screws while unit is in service position.

- Sno-Thro® 1

- TABLE OF CONTENTS 2

- INTRODUCTION 2

- SAFETY DECALS AND LOCATIONS 3

- SAFETY RULES 4

- ASSEMBLY 7

- Deflector Remote 9

- CONTROLS AND FEATURES 11

- 926014, 015 12

- OPERATION 13

- FILLING FUEL TANK 16

- PRE-START 16

- TO STOP IN AN EMERGENCY 17

- STARTING AND SHUT OFF 17

- TRAVELING 18

- TRANSPORT 18

- SNOW REMOVAL 18

- MAINTENANCE 19

- Auger Shaft 20

- Figure 20 21

- SERVICE AND ADJUSTMENTS 22

- 015, 016, 500, 501) 23

- DEFLECTOR REMOTE 24

- DISCHARGE CHUTE 24

- SPEED SELECTOR ADJUSTMENT 25

- ATTACHMENT CLUTCH/BRAKE 25

- ADJUSTMENT 25

- ATTACHMENT DRIVE BELT 27

- REPLACEMENT 27

- FRICTION DISC REPLACEMENT 29

- BATTERY (926500, 501) 29

- SERVICE PARTS 30

- ACCESSORIES 30

- TROUBLESHOOTING 31

- SPECIFICATIONS 32

- Ariens Limited 34

- Warranties 34

(8 pages)

(8 pages) (29 pages)

(29 pages) (33 pages)

(33 pages) (65 pages)

(65 pages) (28 pages)

(28 pages)

Comments to this Manuals